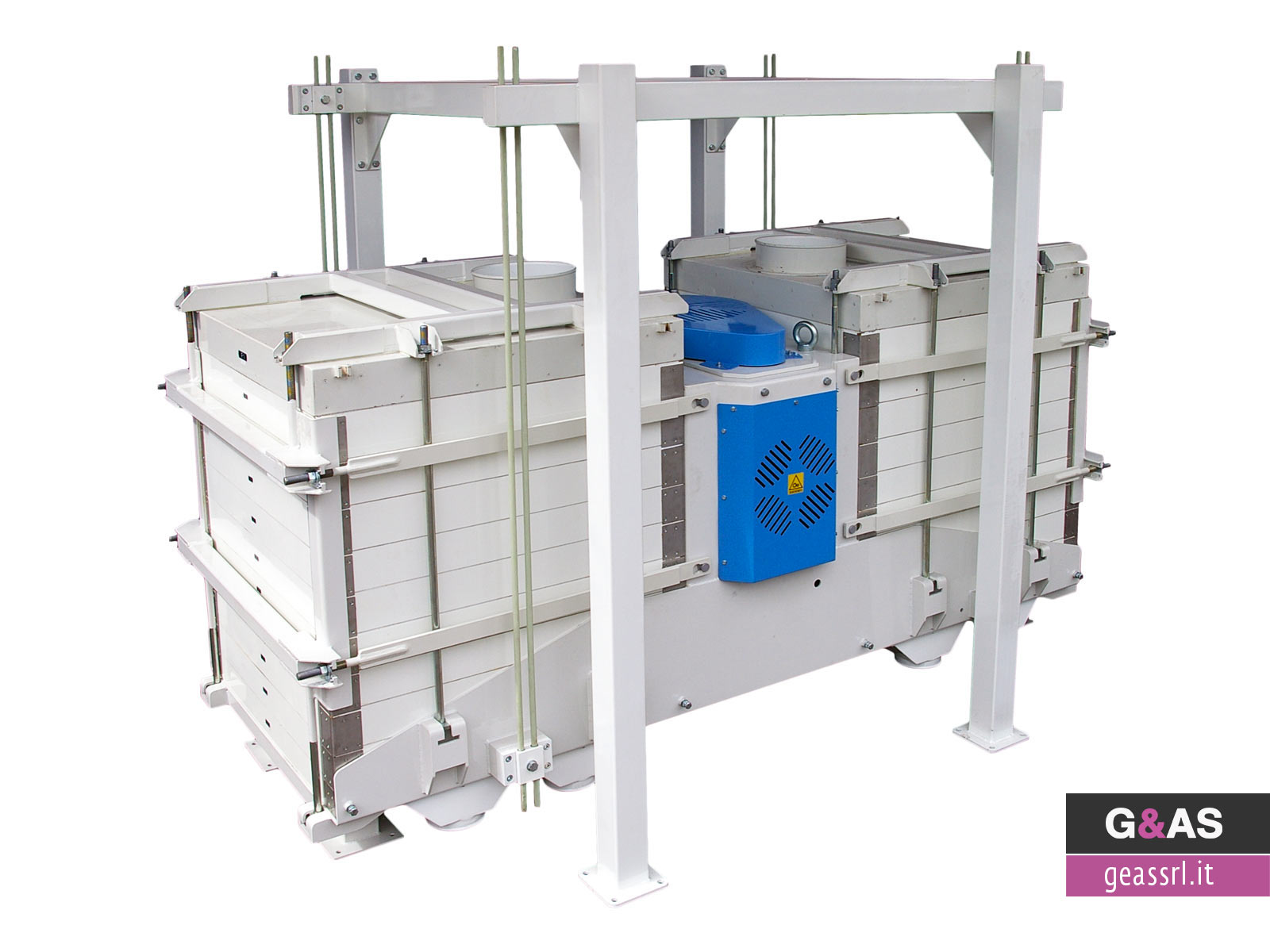

The MONOSIFTER GCPV is used to obtain a granulometric classification or the sifting, of floury or shattered materials. It is often used to sieve the product right before bagging and shipping.

It is composed of a sieves box and a mechanical part that supplies the movement.

The sieves box contains the sifters panels, in an amount that goes from 3 to 12, depending on the capacity and the type of classification to perform. It can be built in wood covered in plastic laminate or, if requested, in aluminium or stainless steel. In every case the machine is compatible with food contact.

The product goes inside the machine from above and start the sieving process from the first sifters down to last ones, using the whole surface available to obtain the maximum efficiency. The product, classified by granulometry, goes out from two or more exits, placed at the bottom of the machine.

The whole sieves box is fixed to the mechanical part underneath, which sustains it and generate the movement. Eight oscillating elements hold up the whole structure, causing the movement. The product that goes in and out is conveyed inside the pipes through sleeves in flexible canvas that allow the machine to move.