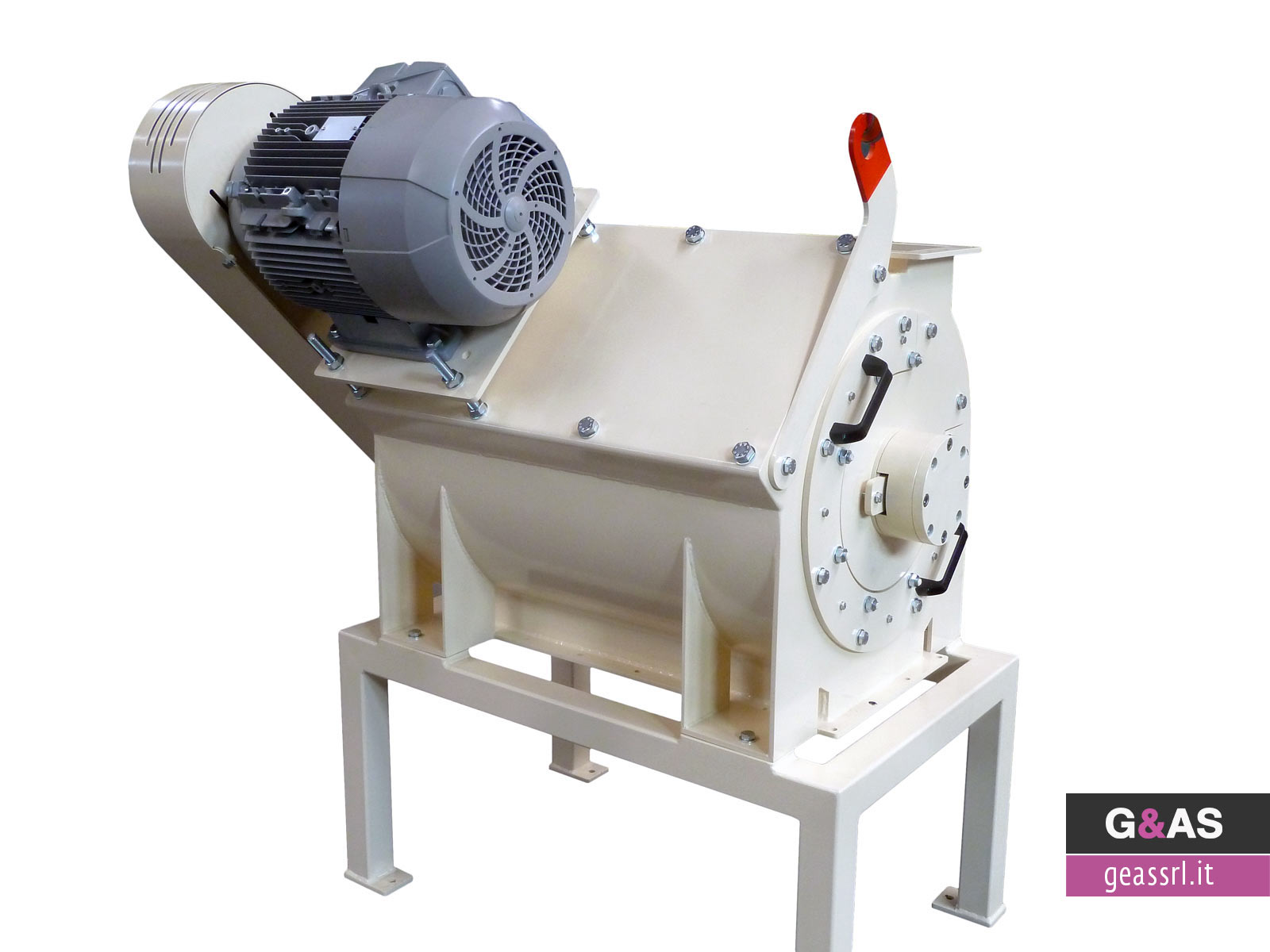

The HAMMER MILL GMAM is an impact grinder.

The impact takes place between special hammers made of stainless steel and a perforated grid: they are both made of a very resistant material.

In milling field this machine is used to grind the wasted materials coming from the wheat cleaning, such as light grains, clothed grains, broken wheat, straws, soy, rye, barley, corn etc. The ground product can then be mixed with by-products.

The hammer mill consists of a power box that allows the product and the air needed for cooling into a grinding chamber in the centre of the rotor. The rotor, which is made of multiple parallel disks, bears some free-oscillating hammers that impact against the product, crushing it.A circular perforated grid holds the large parts in the grinding chamber while the thin ones, crossing it, come out.

Rotating palettes attached to the rotor, but placed outside the grid, act as a fan, putting the grinding chamber into depression, and pushing the ground product towards the tangential exit. In this way the ground product can be pneumatically carried up to a maximum of 15 meters away, where it can be decantated.

For longer distances, a pneumatic suction system must be provided.

A large front hatch gives easy access to the rotor, the hammers and the grid for all maintenance and cleaning operations.